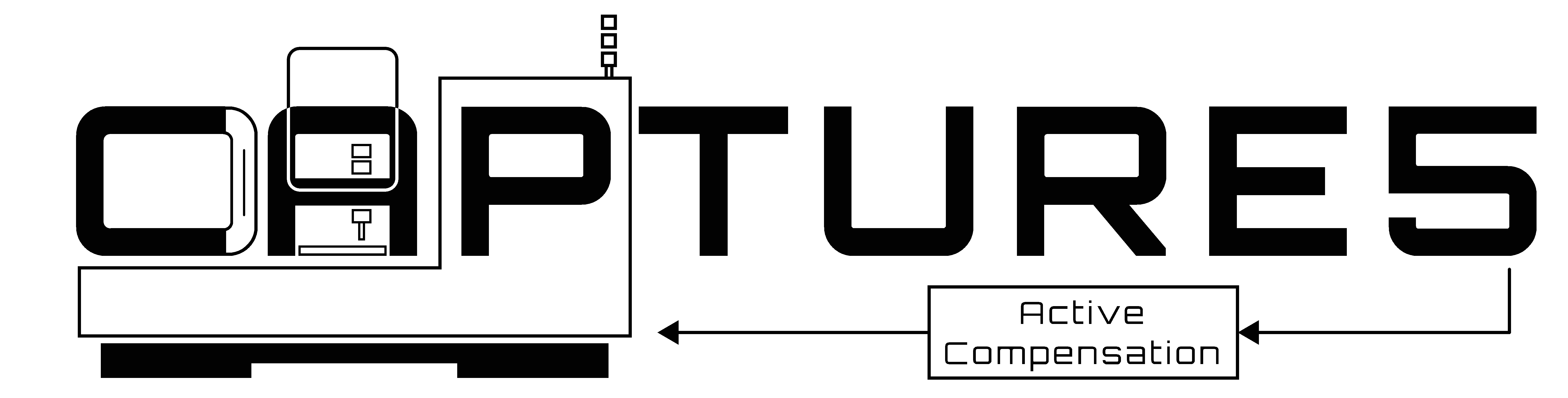

Project : CAPTURES

Compensation active par action sur la rétroaction d’asservissement en position sur machine-outil 5 axes : application à la correction géométrique de la structure.

Real-time compensation of geometric errors on 5-axis machine tool by acting on the position control loop

Summary:

High accurate machining requires error compensation. Among thermally, cutting forces, tool wear, actuators or sensors induced errors, kinematic errors due to geometric inaccuracies has the biggest impact on the final accuracy of the machined part. Furthermore, the addition of rotary axes to linear motion ones in 5 axis CNC machines increases the complexity of performing an accurate position and orientation of the tool. Either mechanical-based or software-based compensation techniques have already been tested in the past. Nevertheless, these last require modification of the post-processor, or of the code or parameters of the NC.

After the establishment of a geometric model of the structural loop based on full-rigid multibody assumption, and an identification process by using in situ measurement, the CAPTURES project aims developing a real-time compensation methodology. Its main objective is to enhance the accuracy of the machine tool, in all its workspace. It will take place in each axis position control feedback loop, in which rotary or linear encoder’s signals will be compensated and sent to the controller. They’re generated thanks to the real position measurement of all the axes and the previously identified geometric model. The CAPTURES block (i.e. embedded controlling system) will have to fit perfectly in the control command chain.

The compensation block CAPTURE5 is inserted into the position control loop of the X-axis. Virtual displacements are manually sent via the human-machine interface (not visible in the video), whereas the position of command is fixed. The NC counterreactions are measured with a ballbar: it wants X to remain stationary but it measures virtual step displacements on his position feedback.

Consortium:

Project Coordinator:

Fabien VIPREY, Associate Professor at Arts et Métiers, LaBoMaP - Arts et Métiers

Project Partners:

Guillaume FROMENTIN, Full Professor at Arts et Métiers, LaBoMaP - Arts et Métiers

Charly EUZENAT, Associate Professor at Arts et Métiers, LaBoMaP - Arts et Métiers

Industrial Partners :

Ugo MASCIANTONIO, Machining referring expert, Machining R&D Manager, Cetim

Laurent LALLIARD, Metrology Engineer EME, Cetim

Romain BRAULT, R&D Project Manager, South-West sector, Cetim

Interns and PhD students:

Flore GUEVEL, Normalienne agrégée de Sciences of Industrial Engineering, PhD Student, September 1st, 2022

______________________________________________

______________________________________________