T. Regnier: PhD Abstract

Cutting forces modelisation and burr height prediction during high speed milling with diamond tools of Aluminium-Silicon alloys.

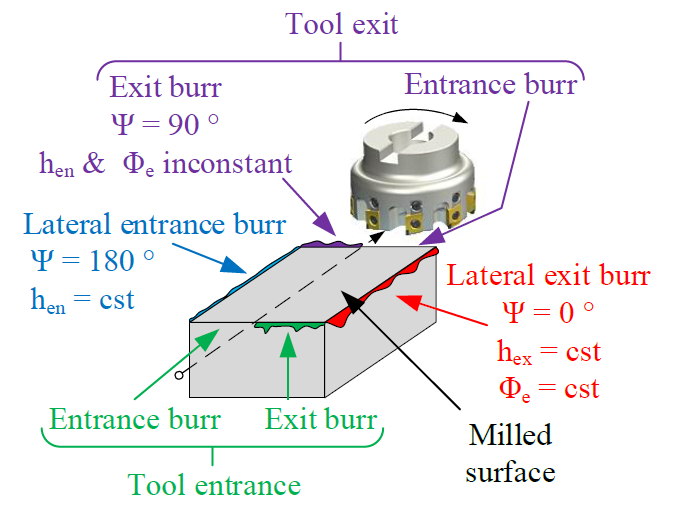

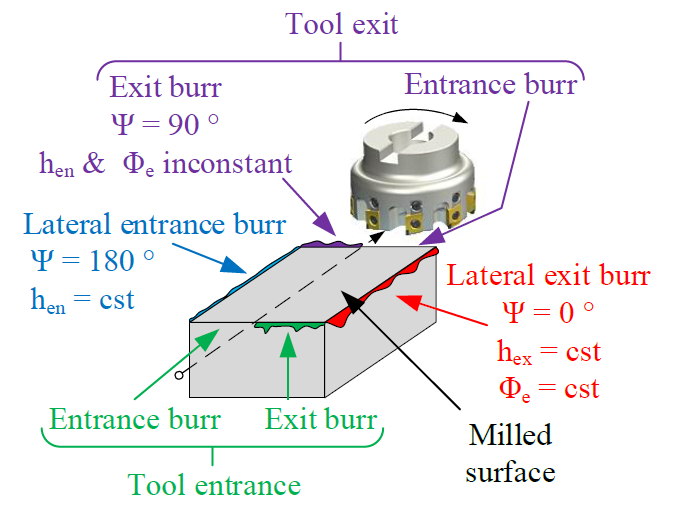

Montupet is an international automotive supplier, european leader of aluminium casting for cylinder blocks. After casting, the top surface of the cylinder blocks is machined in order to permit the assembly with the cylinder head cover. A major issue with machining processes is the burr formation at the edges of the part. In this context of continuous production, burr reduction is crucial, in order to avoid a cost effective deburring process, which represents 30% of the production cost of a part. The aim of the study is to investigate the causes of burr formation in face milling of Aluminium-Silicon alloys and then to find the best ways to reduce it. Firstly, an investigation on the burr formation will be done using high speed camera and DIC software. Then the case of milling will be investigated.

Montupet is an international automotive supplier, european leader of aluminium casting for cylinder blocks. After casting, the top surface of the cylinder blocks is machined in order to permit the assembly with the cylinder head cover. A major issue with machining processes is the burr formation at the edges of the part. In this context of continuous production, burr reduction is crucial, in order to avoid a cost effective deburring process, which represents 30% of the production cost of a part. The aim of the study is to investigate the causes of burr formation in face milling of Aluminium-Silicon alloys and then to find the best ways to reduce it. Firstly, an investigation on the burr formation will be done using high speed camera and DIC software. Then the case of milling will be investigated.