Project : ScCRYO2

Sustainable machining with supercritical dioxide carbon

Summary

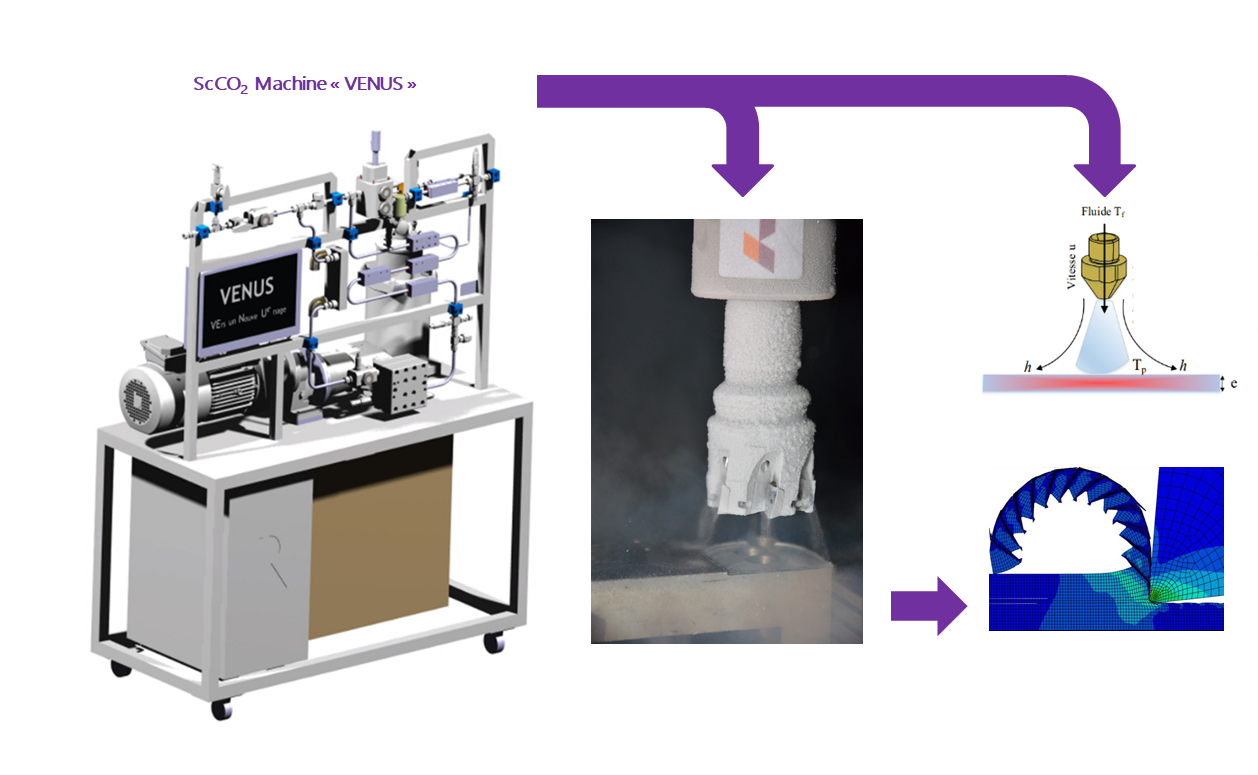

Regarding the economical and ecological challenges of machining difficult-to-cut alloys, this project aims to study a new eco-friendly cooling and lubrication method, using supercritical dioxide carbon (ScCO2). Based on the cooling ability (phase change) and the "green solvent" properties of ScCO2, this project investigates the impacts of ScCO2 on the cutting zone, to understand the thermal and tribological phenomena, for reliable modelisation and improved applications. A special multitasks setup, named "VENUS", has been designed and built by LaBoMaP, to conduct machining experiments with ScCO2 and explore the abilities of the technology. Many laboratories have joined

LaBoMaP to extend as far as possible, the scope of the project, namely,

LIFSE (fluids dynamics),

LAMPA (machining and tribology),

Institut CHAMBERY (life cycle assessment) and

CETIM (Technical centre for the mechanical industry).

Consortium

Project Coordinator

- Frédéric ROSSI, Associate Professor at Arts et Métiers, LaBoMaP

- Gérard POULACHON, Full Professor at Arts et Métiers, LaBoMaP

- Hélène BIREMBAUX, Assistant Professor at Arts et Métiers, LaBoMaP

- Pascal FILIPEK, Technician at Arts et Métiers, LaBoMaP

- François LAFORCE, Machining engineer, CETIM

- AMVALOR’s engineers and technicians, Engineering branch of Arts et Metiers

- Benoit DEBARD, Internship, February to July 2021

- Koffi Samuel KOULEKPA, PhD student, September 2021 to September 2024

- Jason DA SILVA, Work-Study student in electrical engineering, September 2021 to September 2024

Vidéo

Funders