Project : CENTURION

Constitutive modEliNg of the mechanical and tribological behaviors of addiTive manUfactuRed IncONel 718:

application to machining simulation

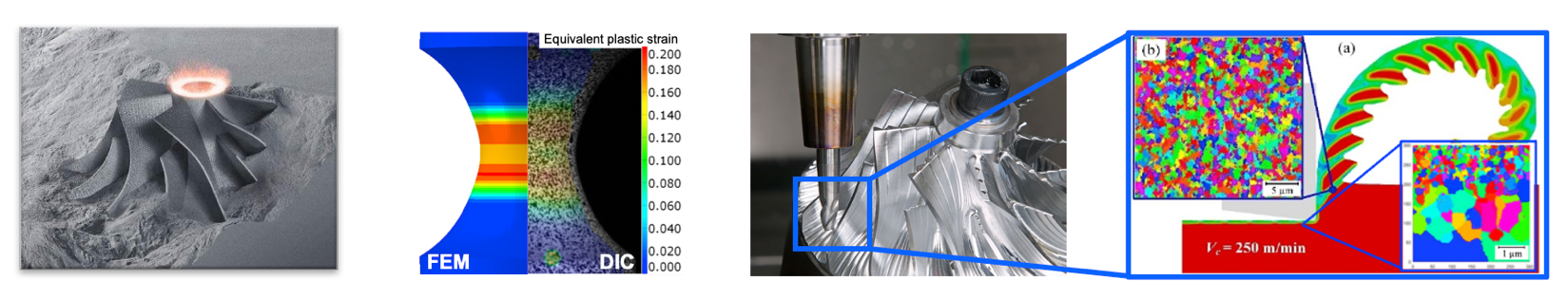

Additive manufacturing (AM) combined with a subtractive finishing (machining) process enables the creation of parts with high complexity, tight tolerances, and good surface finishing. A recent survey highlighted the fact that the limited number of research works on finishing AM parts is not yet able to promote the adoption of AM by several industrial sectors. Therefore, there are considerable research and development opportunities in this area.

This project is centered on AM using Laser Powder Bed Fusion (L-PBF) process followed by machining to produce high quality parts in Inconel 718, without applying post-heat treatment. This can be a challenge since heat treatment is applied to improve the mechanical properties of AM parts, and to relive the high residual stress (RS) levels in the Inconel 718. These stresses can affect the mechanical behavior of L-PBF Inconel 718, thus the machining process. This project contributes for the control the microstructure and RS in the workpiece during deposition by optimizing the L-PBF strategy/parameters, and adjusting the thermal gradients using a heating plate installed on the L-PBF machine.

This project aims to develop an anisotropic constitutive and contact models, combined with an advanced numerical method to accurately simulate the machining of L-PBF Inconel 718. The constitute model should account for most influencing factors affecting the mechanical behavior of L-PBF Inconel 718, including the microstructure and RS. The contact model should consider the extreme tribological conditions in machining. These models together with a phase field approach used to simulate the material separation permit to develop an accurate machining model of L-PBF Inconel 718. This model will be used to investigate the machinability and surface integrity in machining of L-PBF Inconel 718, and to optimize the cutting conditions.

Consortium:

Project Coordinator:

José OUTEIRO, Associate Professor with Habilitation (HDR) at Arts et Métiers Institute of Technology, LaBoMaP - Arts et Métiers

Project Partners:

Arts et Métiers Institute of Technology, LaBoMaP

Guillaume FROMENTIN, Full Professor

Hélène BIREMBAUX, Associate Professor

Dominique COTTON, Associate Professor

University of Lorraine, LEM3

Pascal LAHEURTE, Full Professor

Abdelhadi MOUFKI, Full Professor

Sylvain PHILIPPON, Full Professor

Mohammed NOUARI, Full Professor

Gael LE COZ, Research Engineer

Andréa CAPELLA, Research Engineer

MINES Paris | PSL Research University, ARMINES of CEMEF

Katia MOCELIN, Full Professor

Daniel PINO MUNOZ, Associate Professor

Yancheng ZHANG, Associate Professor

Selim KRARIA, Research Engineer

Interns and PhD students:

Arts et Métiers Institute of Technology, LaBoMaP

PhD student to be hired

Two Master students to be hired

University of Lorraine, LEM3

LEM3 laboratory of the University of Lorraine: Paul DIDIER, Postdoc, March 2023 to August 2024

Master student to be hired

MINES Paris | PSL Research University, ARMINES of CEMEF

PhD student to be hired

______________________________________________

______________________________________________

![[title-image]1292585541972[/title-image] [legende-image]1292585541972[/legende-image]](https://anr.fr/typo3conf/ext/anr_skin/Resources/Public/assets/img/anr-logo-2021.png)

![[title-image]1292585540887[/title-image] [legende-image]1292585540887[/legende-image]](https://www.armines.net/sites/all/themes/armines/assets/images/armines-logo.png)