Project: BOOST

BOOST

(Le BOis pOur les STructures des véhicules)

Title / Titre: Wood for vehicle structures : local mechanical and physical characterization of veneers for optimized structure design / Le Bois pour les structures des véhicules : caractérisation mécanique et physique locale de placages pour la conception optimisée de structures

Start date: 01/11/2021

Period: 3 years

Total budget: 735928 €

Collected budget / subvention for LaBoMaP: 197 k€ (of a total budget of 395 k€ for LaBoMaP)

Funding: ANR PRC

Project bearer: ICA – Université de Toulouse

Project coordinator : Bertrand MARCON

Mots clés: Bois, Structure, Véhicule, Térahertz, Caractérisation, Placage, Déroulage

Keywords: Wood, Structure, Vehicle, Terahertz, Characterization, Veneer, Peeling

BOOST on the ICA web page

Abstract:

This ANR BOOST project is a multi-partners project (three laboratories), which aims to demonstrate the possible integration of wood, as laminated veneer products, in the transport industries (aeronautic, naval, rail automobile sectors). Its usage as a structural material is encouraged by the interesting ratio of its mechanical properties to its density, as well as its environmental impact when both local production and transformation are adopted.

Nowadays, the use of local resources is motivated in the bioeconomic context. This explains the strategy adopted in the BOOST project, which is mainly focused on the plywood due to its low cost. Moreover, the project focuses on two local hardwood species, the poplar and the beech, widely available in the French territory. Despite the variation of its mechanical properties, these species are considered as homogeneous woods. This explains its common use in the peeling industry. For a better valorization of these species and a better control of the manufacturing cost, the material defaults such as the knots, the local variation of the fiber orientation and the cracks within the veneer thickness induced during the peeling process have to be addressed the fact that they strongly affect the mechanical properties of the engineered products.

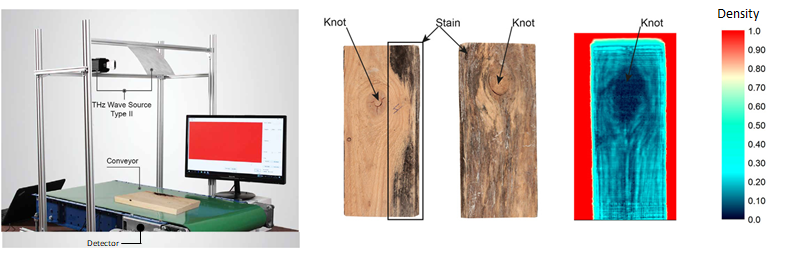

The main goal of this project is to measure the local density of veneers with light instruments, easily transferable from the lab scale to the wood sector, for online measurements during the peeling process. The purpose is to develop a global system able to determine simultaneously the local properties of veneers including its density, the local orientation of fibers and the veneer checks; during the online industrial flow. A recent and promising technology for the local density measurement, based on Terahertz waves, is exploited (see Figure 1). The innate advantages of this technology are summarized by the use of non-ionizing rays (in contrast to X-Ray technology) and its adequacy with rather low thicknesses of veneers (and eventually saw boards).

Figure 1: A Terahertz densimeter for the determination of wood properties [Terasense Group, Inc.]