ARRIBRAVE : an innovative platform for unraveling machining physics

le February 9, 2026

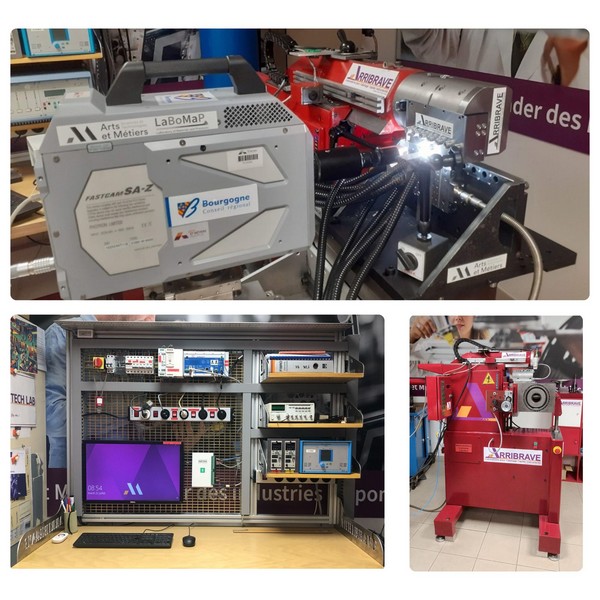

The ARRIBRAVE platform (Automated Rig for Rapid, Instrumented Laboratory Planing with Experimental Value) is a dedicated tool for in situ investigation of the physical phenomena involved in the cutting of metallic and composite materials.

A historic machine redesigned for advanced research

Originating from the refurbishment of a historical shaping machine, ARRIBRAVE has been transformed into a highly instrumented test bench capable of reproducing orthogonal cutting with high precision. This €400k project, initiated at the end of 2023 and scheduled for completion in May 2026, has been led by Jihane Arbi, Hélène Birembaux, and Frédéric Rossi, members of the Materials and Processes Laboratory (LaBoMaP).

ARRIBRAVE provides LaBoMaP researchers with a true in situ observatory for chip formation and the fundamental mechanisms underlying machining processes.

“Matter does not lie — but one must ask it the right questions, and above all observe and listen to it,” explains Associate Professor Frédéric Rossi. “ARRIBRAVE was conceived as a genuine generator of experimental data rather than a simple test machine. Transforming a historical machine enabled us to create a controlled, robust, and shared tool serving the entire team and addressing fundamental questions related to cutting.”

Cutting‑edge, fully integrated and automated instrumentation

The platform enables the exploration of major phenomena associated with cutting: surface integrity, cutting forces, heat fluxes, friction, strain hardening, and microstructural alterations.

These analyses are essential for improving the surface integrity of machined components, optimizing tool life, and strengthening the reliability of predictive models.

“ARRIBRAVE stands out thanks to its cutting‑edge instrumentation, which is fully integrated and automated, ensuring the acquisition of synchronized, multiphysics data with high reproducibility. This approach enhances experimental efficiency and allows researchers to focus on high‑value scientific analysis,” notes Associate Professor Jihane Arbi.

A wide range of sensors and observation systems

ARRIBRAVE brings together a comprehensive suite of sensors and diagnostics tools: force sensors, piezoelectric and semiconductor gauges, high‑speed visible and infrared cameras, digital image correlation systems, and chromatic confocal sensors.

These multi‑scale measurements allow the combination of kinematic and thermal fields. The collected data feed and validate numerical and hybrid models (Abaqus, FEM, inverse identification), contributing to research on fatigue and the integrity of machined components.

A major asset for LaBoMaP’s collaborative projects

Thanks to its ability to bridge fundamental physical phenomena with industrial performance, ARRIBRAVE constitutes a strategic tool for LaBoMaP and its partners.

The platform is now mobilized in numerous collaborative projects, reinforcing the laboratory’s expertise in the understanding and control of machining processes.